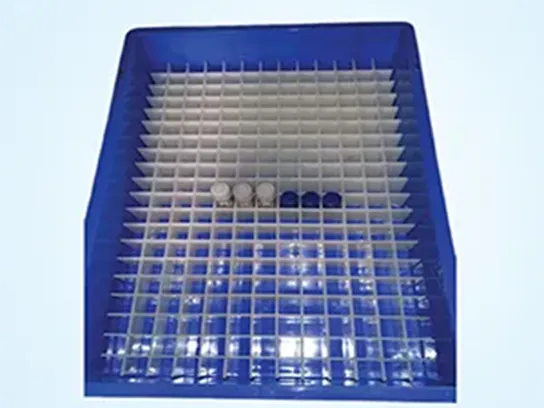

Fabricated HDPE Crates

Fabricated High-Density Polyethylene (HDPE) crates are emerging as frontrunners in this space, offering a plethora of advantages over traditional packaging materials like wood, metal, or cardboard. Let’s dive into the world of fabricated HDPE crates and explore why they are becoming the go-to choice for industries worldwide.

Durability That Stands the Test of Time

HDPE crates are renowned for their exceptional durability. Unlike wooden crates that can warp, rot, or suffer from pest infestation, or metal crates that may rust and corrode, HDPE crates withstand harsh environments, chemicals, and even impacts during transportation. This resilience extends the lifecycle of the crates, making them a cost-effective solution for businesses looking for long-term packaging options.

Sustainability – A Step Towards a Greener Future

In an era where environmental consciousness is paramount, HDPE crates shine brightly. Being recyclable, these crates contribute significantly to reducing the environmental footprint of packaging operations. The fabrication process of HDPE allows for the efficient use of materials, further minimizing waste. By choosing fabricated HDPE crates, businesses not only meet their packaging needs but also align with global sustainability goals.

Flexibility and Customization at Its Best

One of the most compelling advantages of fabricated HDPE crates is their versatility. These crates can be custom-designed to fit specific dimensions, weights, and shapes, accommodating a wide range of products from different industries. Whether it’s for agricultural produce, automotive parts, or electronic components, HDPE crates can be tailored to offer optimal protection and functionality.

Enhanced Protection for Your Products

The structural integrity of fabricated HDPE crates ensures that the contents within are shielded against external pressures, impacts, and even weather conditions. This level of protection is paramount for industries where the safe transport of goods is critical. Moreover, the non-porous surface of HDPE crates makes them resistant to moisture and easy to clean, further safeguarding the products from potential damage and contamination.

Cost-Effectiveness Without Compromise

While the initial investment in fabricated HDPE crates may be higher than in traditional packaging options, the long-term savings are undeniable. Their durability reduces the need for frequent replacements, and their lightweight nature can lead to significant savings on shipping costs. Additionally, the minimal maintenance required for HDPE crates further adds to the cost-effectiveness, making them an economically sound choice for businesses.

Ease of Handling and Transportation

The design of HDPE crates often incorporates features that make handling and transportation a breeze. From ergonomic grips to interlocking structures for secure stacking, these crates are built with the end-user in mind. The lightweight nature of HDPE further eases the strain on workers, enhancing workplace safety and efficiency.

Conclusion

Fabricated HDPE crates represent a confluence of durability, sustainability, and versatility, making them an indispensable solution for modern packaging needs. As businesses continue to seek out packaging options that offer economic and environmental benefits without compromising on quality, HDPE crates stand out as a clear choice. Adopting these innovative crates can not only streamline operations but also contribute to a brand’s reputation as an eco-conscious and forward-thinking enterprise. The advantages of fabricated HDPE crates are clear, and their role in shaping the future of packaging cannot be overstated.